The Ever-Evolving Fabrication Industry: A Journey of Innovation and Advancement

The fabrication industry, once characterized by manual labor and traditional manufacturing methods, has undergone a remarkable transformation over the years. In today’s fast-paced technological landscape, innovation is driving the evolution of fabrication, empowering businesses to achieve unprecedented levels of precision, efficiency, and customization.

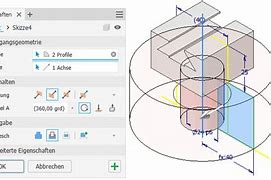

Digitalization and Computer-Aided Design (CAD)

One of the most significant drivers of evolution in fabrication is the widespread adoption of digital technologies and Computer-Aided Design (CAD) software. These tools have revolutionized the way products are designed and fabricated. With CAD, engineers and designers can create detailed 3D models, allowing for virtual prototyping, faster iterations, and better collaboration. The shift to digital design has significantly reduced lead times and minimized errors, enabling fabrication companies to offer more complex and customized products to their clients.

3D Printing

Additive manufacturing, commonly known as 3D printing, has emerged as a disruptive force in the fabrication industry. Unlike traditional subtractive processes that involve cutting away material, additive manufacturing builds objects layer by layer using materials such as plastics, metals, and even ceramics. This technology opens up new possibilities for intricate and lightweight designs that were previously unattainable. 3D printing is increasingly used in aerospace, medical, automotive, and other industries, offering enhanced customization, reduced material waste, and faster production cycles.

Automation and Robotics

Automation has become a driving force in many industries, and fabrication is no exception. Robots are now utilized for tasks such as welding, material handling, and assembly, resulting in higher productivity, improved safety, and reduced labor costs. collaborative robots (cobots) are also playing a significant role in fabrication, working alongside human operators to enhance efficiency and streamline processes. Automation is reshaping the industry by augmenting human capabilities and tackling repetitive and labor-intensive tasks, leaving the workforce to focus on more complex and creative aspects of fabrication.

Rethinking Leadership and Management in Automated Environments

With automation transforming how work is done, the role of leaders and managers is evolving as well. Effective leaders will need to understand how to leverage automation technologies and foster a culture of continuous learning and innovation to thrive in this new era of work.

Internet of Things

The integration of the Internet of Things (IoT) into fabrication processes is revolutionizing the way machines communicate and operate. IoT-enabled sensors collect real-time data from machines and equipment. This assists with…

- enabling predictive maintenance

- optimizing production schedules

- and reducing downtime

The interconnectedness of devices in smart factories fosters greater agility and responsiveness in fabrication operations, leading to increased productivity and cost savings.

Advanced Materials and Coatings

The availability of advanced materials and coatings has opened up new avenues in fabrication. From high-strength alloys and composites to self-healing and anti-corrosion coatings, these innovations enhance the performance and durability of fabricated products. Advanced materials are driving progress in aerospace, defense, renewable energy, and other critical sectors, pushing the boundaries of what is possible in the fabrication industry.

Sustainable and Green Initiatives

Sustainability has become a key driver in the fabrication industry’s evolution. Companies are increasingly adopting eco-friendly practices, such as recycling and waste reduction, energy-efficient processes, and the use of sustainable materials. Embracing green initiatives not only aligns businesses with environmental goals but also addresses the growing demand for sustainable products from environmentally conscious consumers.

Customization and Personalization

The fabrication industry is moving away from mass production towards greater customization and personalization. With digital design tools and advanced manufacturing technologies, businesses can create highly tailored products to meet specific customer requirements. This shift towards customization has revolutionized the consumer goods, healthcare, and automotive sectors, enabling companies to provide unique solutions that cater to individual needs.

The fabrication industry is on an exciting journey of evolution, driven by technological breakthroughs, digitization, automation, and sustainability. The integration of digital design tools, additive manufacturing, robotics, IoT, and advanced materials has transformed the way products are conceptualized, designed, and fabricated. The focus on customization and personalization has opened up new opportunities for businesses to cater to diverse customer demands.

As this evolution continues, the fabrication industry will witness even more remarkable advancements, shaping the future of manufacturing across various sectors. Embracing innovation, sustainability, and digitalization will be paramount for fabrication businesses to stay competitive and meet the demands of an ever-changing market. The fabrication industry’s evolution is a testament to human ingenuity, and it paves the way for a more efficient, sustainable, and interconnected future of manufacturing.