Customer, Challenge & Risks

Solution

Thankfully, our customer was familiar with Pioneer Industrial Systems since they already had our high-speed automatic dial spray machines. A sales engineer was on-site within a week to further understand the challenges, constraints, and requirements of the system. Due to the manual load and unload, this portable unit would only be used on passenger tires, which lead Pioneer to use the HTS100i design.

Our engineers have been working with the tire industry since the late 1980s, so we understood the importance of keeping the mold release inside the tire and what a mess the overspray could make. We also used our history of spray booth projects to provide a three-sided open face spray booth that included many other benefits. After providing the customer with a proposal that highlighted our prior experience with tire spraying technology and collection, along with low-cost and portability, the unit was approved and a purchase order was issued.

Pioneer started its defined Machine Building Process. After the customer runoff and training at our facility, the machine was shipped. Since the unit was self-contained and designed to be portable, installation was not needed. They simply put it in place, plugged it in power and hooked up to plant air. The customer was given support documents, a spare parts list, and was well taken care of after shipment.

Outcomes of Success

Overall, the project was very successful. The system was shipped and installed by the customer. The spray was contained with minimal to no overspray getting outside of the spray booth. The plant engineer was involved throughout the project, so he was always aware of status, any obstacles, and felt comfortable through the entire design and build process. Mold release consumption was controllable and containable, which was a substantial cost savings in both material consumption and labor involved. The primary purpose of allowing production to continue was achieved.

The machine performed quite well as a manual loaded automatic spray booth that was portable, could be moved around as needed, and allowed the customer to maintain production while taking down any of the high-speed spray cells for routine maintenance.

Paint, Dispense, & Spray

Low Cost Solutions

Modular Designs

Model: HTS100i

Horizontal Tire Spraying (Inside Spray)

HTS100i Advantages

COST

- Manual setup

- Low cost manual load/unload

QUALITY

- Manual fluid regulator

- Manual spray gun adjustment

- Paint entire 360 degree inside

- Spray based on timer

SERVICE

- Easy access maintenance

- Replaceable filters

- Quick change spray gun

- Ease of installation

- Spare parts

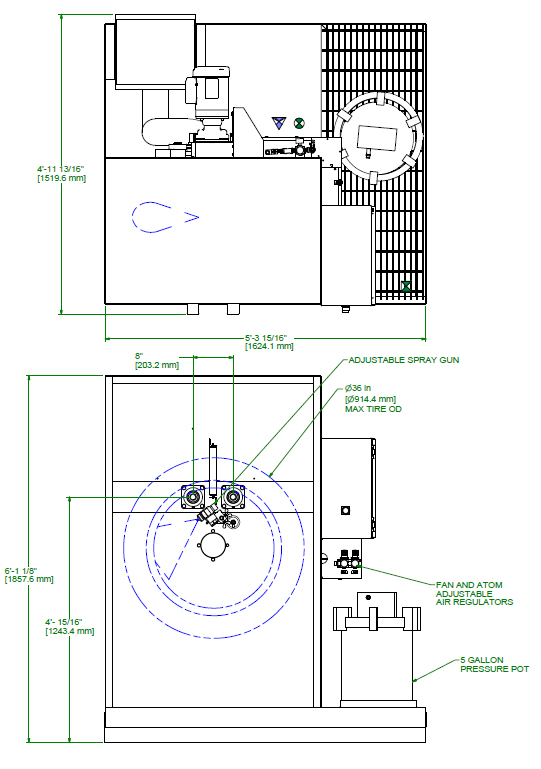

HTS100i Feature Highlights

Adjustable timer to allow tire to get up to speed prior to painting. Potentiometer to adjust tire rotation speed. Push button starts & keeps the tire rotating. Tire stops when the button is released.

Quick change spray gun & manually adjustable positioning of the spray gun.

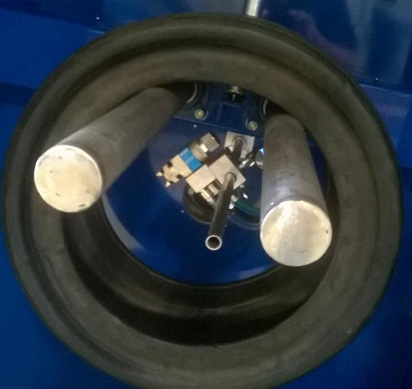

Knurled rollers to provide grip.

5 gallon Stainless Pressure Pot.

Modular Design with Integrated Exhaust

Manually adjustable regulators for Fan and Atom air pressures.

Wet mist collector with Secondary HEPA filter.

| HTS100i Specifications | ||

| Bead Diameter | 12″ – 24″ | 305– 610mm |

| Tire Width (bead bead) | 6″ – 24” | 152– 610mm |

| Tire OD Diameter | 16″ – 36” | 406– 915mm |

| Max Tire Weight | 85lbs | 38.5kg |

| Inside Tire Spray | 360 degrees | |

| Cycle Time (tph) | Approximately 180 | |

| Cycle Time (tpd) | Approximately 4,320 | |

| Tire Measurement | N/A – manually adjusted by operator | |

| Bar Code Reader | Optional | |

| Spray Gun | Quick change manifold | |

| Spray Gun Pattern | Variable fan manually adjustable control | |

| Fluid Delivery | 5 gallon Pressure Pot | |

| Atomizing Air | Variable manually adjustable control | |

| Tire lube | Water based system | |

| Water Purge | Not Standard | |

| Infeed conveyor | N/A—Manual load/unload | |

| Electrical Service Req’d | 480v/3ph/30amp or 380V | |

| Air Service Req’d | 80psi @ 3/4″inlet | |

| Water Service Req’d | NONE | |

| Machine footprint | 5′ x 5′-4” | |

| Overall Height | 6′-2” | |

| Exhaust Fan | 1 hp | 300 cfm |

| Dual Filters | Secondary HEPA filter | |

| Backdraft booth | Powder Coated Steel | |

Pioneer’s HTS Green Tire Sprayer is ideal for Radial or Bias-Ply Passenger, Utility, Trailer, and AG Tires.

Our pressure pot spray system provides the low cost solution you need for spraying green tires.