Labor Shortage Affecting Manufacturing - Automation Can Help

Keeping your company’s name in the game is beginning to become tricky as the amount of competition grows and attempting to keep up with others is difficult as fewer people are available to work. Many industries are realizing that the labor shortage is becoming the root of their problems, as this has been an issue for quite some time and will be for years to come. How is there such a great change and gap within the labor force today and how can manufacturers keep moving forward with these industry pains?

The Peak Of Manufacturing

According to the U.S. Chamber of Commerce, as of June of 2022, 11.4 million jobs are unfulfilled within the U.S. and at the same time, there are around 6 million people who are currently unemployed in our nation’s labor force. The Bureau of Labor Statistics broke down the labor shortage data by industry showing that the manufacturing industry alone stands with an open job rate of 7.3%.

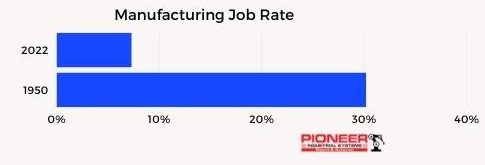

One of the top filled industries within the U.S. was proudly the manufacturing industry, but over time, that has changed substantially.

It is no secret that the manufacturing industry has been on a constant decline for years now. According to the U.S. Bureau of Labor Statistics, when the industry in the United States was at its peak in 1950, the filled job rate within manufacturing alone was at 30.2%, making it the most populated industry of all. Since then, the number continues to drop.

Baby Boomers Creating An Impact

As of 1950, in the early stages of the Baby Boomer era, the United States population consisted of 158.8 million citizens. The Baby Boomer generation ranged from 1946 to 1964, resulting in an addition to the U.S. population of 71.6 million people.

While the population remained steady for the time being since the Baby Boomers, Millennials started to come into the picture. The Millennial generation ranged from 1981 to 1996, bringing even more citizens into the U.S. More babies had been born during this time period than in the Baby Boomer stage, setting the record at 72.1 million more people.

The U.S. population had leaped from 158.8 million in 1950, to around 281.7 million U.S. citizens in the year 2000. Macrotrends data explains that over two decades later, the U.S. population has jumped to 332.9 million citizens. With the large increase in the population, you would think over time, as generations become older, a steady number of individuals would enter the skilled trades and traditional workforce at a constant pace, but that is simply not the case.

The Labor Gap Explained

Currently, the sizes of families are not as large as they use to be. The decline in the size of families started in the fifties, with an average family size of 3.76 people, whereas the number of people per family is currently around 2.6.

The age at which women had children plays a great role in the labor gap. From demographic research, about 50% of women in 1950 had children in their early twenties. This trend has also shifted as women in today’s day and age are more prone to working and focusing on themselves instead of staying at home and raising children. More recently, NBC News claims women are changing what use to be traditional and decided to wait to start families until their 30s or 40s.

Women are putting off childbearing for plenty of reasons, a couple of those being:

- Investing more time into getting a degree

- The desire to have a stable income

- Having to use their education to become financially stable to raise children

Overall, the age of starting a family has been changing for some time now and will continue to change. This change has resulted in our labor force having a great gap between the number of retiring employees and the low number of workers entering the workforce, since aged workers are not as common as they once were, this leaves employers to replace these “senior” employees with people with less experience and accomplished time in their careers.

A Larger Population Creates A Larger Demand

The larger population is known to increase the demand market, resulting in the need to increase supply for the growing population.

The demand for certain goods and services is constantly increasing over time, keeping manufacturing industries and their employees busy at work.

Aside from the gap in the labor force, more recent generations like Millennials have no desire to enter the manufacturing industry as previous generations did. With the number of workers retiring on track or retiring earlier, and a lower number of current or incoming workers, the gap is going to be difficult to overlook.

The stigma behind working in the manufacturing environment and the work experience of baby boomers, leaves a mark on the younger generations, leading them to believe that being a part of the manufacturing industry is the last thing they should aim toward in a career. It is highly encouraged to go straight into a four-year program after high school, giving students the impression that it is their only option if they want to succeed in life.

The previous retiring generation’s experience and opinions had given the manufacturing industry a bad representation, leading younger generations to believe they should look for work in other industries.

Reasons there is a poor representation of the manufacturing industry include:

- Low, degrading pay

- Hazardous working conditions

- Hot, dark, non-air-conditioned environments

- Monotonous job tasks

But these working environments have moved past this unattractive representation, and many do not realize that.

The Future Of Manufacturing

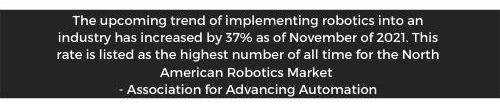

More recently, manufacturers have been reshoring. Producers want to bring more manufacturing back into the United States. Implementing automation, or more automation, into the manufacturing industry may be in the manufacturer’s best interest as labor is hard to come by.

Many think of an “assembly line” when they imagine working within the industry when truly, manufacturing has taken a huge leap from past processes. This industry has become eager to recruit employees with more up-to-date skill sets. Skills that are beneficial when it comes to working hand-in-hand with new automated systems that improve processes. These types of jobs consist of

- Robot/PLC Programmers

- Software Engineers

- Robot Technicians

- Industrial Electricians

- Industrial Maintenance Technicians

And many more. These jobs seem to be overlooked, and many do not realize that these opportunities exist within the industry and that there is a huge need for them. Alongside these rewarding jobs, companies are willing to offer competitive benefits to work within improved environments that are equipped with robotics and automation.

As the need for jobs with an advanced skill set increases, generations should be reminded that these jobs are available within manufacturing industries.

The Stigma Around Manufacturing Jobs

Many believe that implementing robotics into the workforce removes workers from their jobs completely. The truth is, robotics and automation create the need for more rewarding careers and can shift human workers to tasks that are more enjoyable and productive to the company, leaving robots to complete tedious and dull work. Other jobs that workers are transitioned to are just as important within the process. Many do not realize that workers can also be trained to work with robots that need human collaboration.

Assigning different work to humans and leaving dangerous and tedious work to robots can also increase the total factor productivity within the workplace.

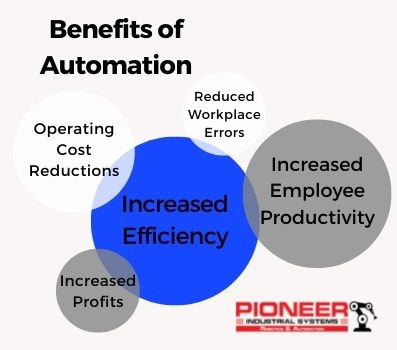

The number of industries that have implemented automation into their manufacturing processes continues to rise and is beneficial as it can fill the need for employees throughout the ongoing labor shortage. Automation comes with many benefits aside from filling positions, including creating safer, more efficient processes while increasing –

Quality

- Integrating robots into your manufacturing results in more precise outcomes. Robots have the capacity to repeat the same task over and over, creating the same great result no matter how monotonous the task may be.

Productivity

- Robotics can perform for a longer period, keeping efficiency at a high by continuously completing work, resulting in an increase in profits for the company.

Consistency

- The work being done by robotics can remain equal and precise within the workplace, not requiring a break or day off – reassuring the employers that work will continue to carry on without the worry of giving an employee a break.

The Three D’s

Many robotic and automation integrators use The Three D’s to decide and explain why automation makes sense for them.

- Dangerous

- Dirty

- Disengaging

Dangerous:

- Robots and automated processes are an excellent option to perform dangerous jobs in manufacturing processes. Not only does this remove human employees from dangerous situations day in and day out, but it also brings down insurance costs for employers as well while not having to worry about worker’s compensation.

Dirty:

- Many robot manufacturers have models for purchase that can be pressured washed and are resistant to heat, dirt, paint, and other chemicals. Throughout the manufacturing industry, there are many jobs and processes that require the employee to be in those dirty situations, whether it be where they may get wet, dirty, or exposed to chemicals in the air.

Disengaging:

- When most people think of manufacturing, they think of people standing next to conveyors on assembly lines doing the same job or inspecting the same product over and over all day long. Although manufacturing has changed dramatically over the last couple of decades, there are times and processes that still require monotonous jobs. This can lead to employees feeling undervalued, unfulfilled, and becoming bored on the job. Automation can help avoid this by placing a robot to do those jobs and open other opportunities for those same employees to fill more rewarding positions.

Reevaluating Company Spending

The three D’s can be used as a hiring tool as well. Companies with robots performing dangerous operations in their process no longer must tell potential hires that they must be in a dangerous, unpleasant work environment, needing to sit or stand trying to pay attention and focus on tedious and tiresome jobs for 8 – 10 hours per day.

Like other industries, these manufacturing companies are trying anything and everything to fill their open positions and can get stuck spending a great amount of time and money, whether it be advertising job postings, sign-on bonuses, or increasing wages to entice people to accept open positions.

These costs could be money those companies could put towards integrating robotics into their processes to perform the work. Not to mention, the amount of overtime, paid time off, and bonuses in addition to an employee’s regular pay. This money could be put towards new systems on your factory floor.

Benefiting Your Company

With the current labor shortage and growing demand, many companies may not have a choice but to integrate robotics and automation into their existing manufacturing processes. Furthermore, companies who do not may find themselves losing out on opportunities with their competitors leaving them behind. This is where our services come in.

Here at Pioneer Industrial Systems, we’ve been helping companies integrate automation into their manufacturing for over 20 years.

Our team of robotics and automation experts can guide you through the challenges of automation from initial concept to factory floor installation. Let us be your guide to ensure your project is a success!

Click Here to Book a Free Consultation Call with One of Our Automation Experts Today!