DTS1000i Case Study

Customer, Challenge & Risks

Our customer was a global tire manufacturer. He wanted to replace an old worn out spray machine that was manually loaded with a new piece of equipment that could be conveyor fed with improved spray characteristics and reduced labor.

Another challenge was the variation of tires through the spray system. To minimize Work-in-Process, the tires would no longer be produced in batches stored on tire carts but enter the system completely randomly via a conveyor system.

Solution

Thankfully, our customer had been introduced to Pioneer Industrial Systems through prior projects at other plants. After a brief discovery call, a sales engineer was on-site within a week to further understand the challenges, constraints, and requirements of the system.

Our engineers have been working with the tire industry since the late 1980s, so we understood the importance of minimizing overspray, meeting high-speed cycle time, and spraying a wide range of tire sizes. This plant primarily built passenger tires, so a DTS1000i would be perfect for this application.

Since the plant had two older Dial Index Tire Spray machines, it was determined to stay with a rotary style DTS machine, but one that could provide more output and improved spray characteristics.

A project that we had completed about four years prior had involved a fully enclosed spray booth that included many other benefits.

Pioneer had completed several successful tire spraying machines, white wall spraying machines, tire marking machines that operated in a dual-mode, with both recipe and adaptive intelligence. This dual-mode resulted in a precise spray and maintained consistent uptime, with tires entering the system entirely at random.

After discovering the customer’s needs, the sales engineer provided the customer with a proposal that included advantages of our PFDS and cycle time analysis. With this data, the customer was able to sell the tire spray machine to leadership easily. It was approved within the budget, met the required specifications, and a PO was issued.

Pioneer started its defined Machine Building Process. After the customer runoff, the machine was disassembled, shipped, and Pioneer’s assembly crew went on-site to install the equipment. The engineer then stayed on-site the following week to connect our system to the plant conveyors and higher-level server and a few days of commissioning and training.

The customer was given support documents and was well taken care of after the startup was completed.

Outcomes of Success

Overall, the project was very successful. The system was installed on schedule. The spray was contained with minimal to no overspray getting outside of the spray booth.

Cycle times were better than initially anticipated.

The plant engineer was involved throughout the project, so he was always aware of status, any obstacles and felt comfortable throughout the entire process.

Mold release consumption was considerably lower than comparable machines due to our Precision Fluid Delivery System, which was a substantial cost saving.

The machine performed so well that the plant wants to replace the second unit as soon as they can get their budget approved.

Material Handling

Paint, Dispense, & Spray

High-Speed Production

Software & Data Integration

Installation

Startup Support

DTS1000i Advantages

- 10-12 tires per minute

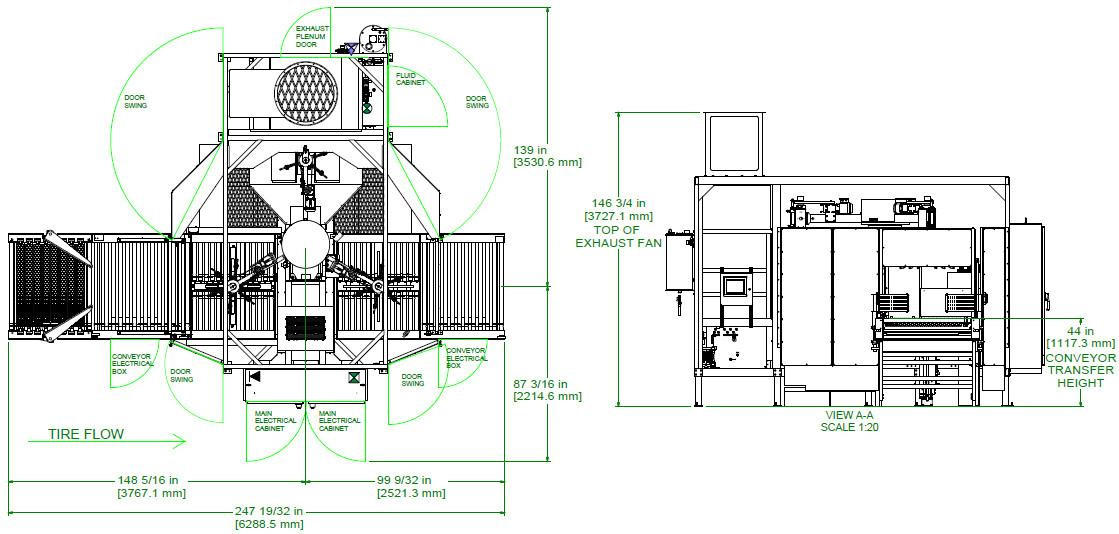

- 3 station infeed conveyor with a centering station, accumulation station, and servo lift station

- 2 station outfeed conveyor with a pneumatic lower station and accumulation station

- chuck drives for tire rotation

- Automatic chuck cleaning each index

- Fan air for the spray gun automatically adjusts to optimize spray pattern to each individual tire.

- Spray gun position servo controlled relative totire

- Tires gently lowered to the take away conveyor

- Integrated tire measurement for OD/ID & Height

- Individual height

- Polycarbonate guards provide improved air flow at the paint booth

Available Options

- Right hand or left hand orientation available

- Additional accumulation zones, infeed or outfeed conveyors

- Emergency cable pulls for the conveyor

- Larger pressure pots

- Agitator for pressure pot

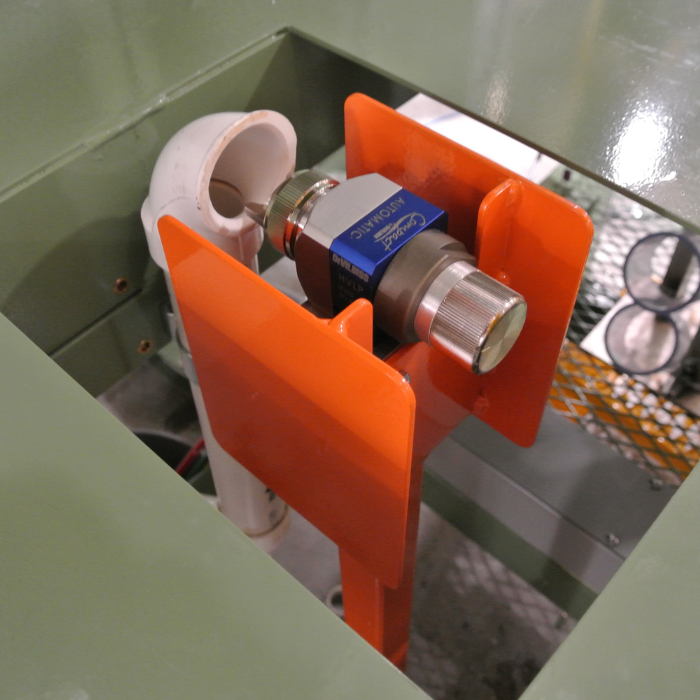

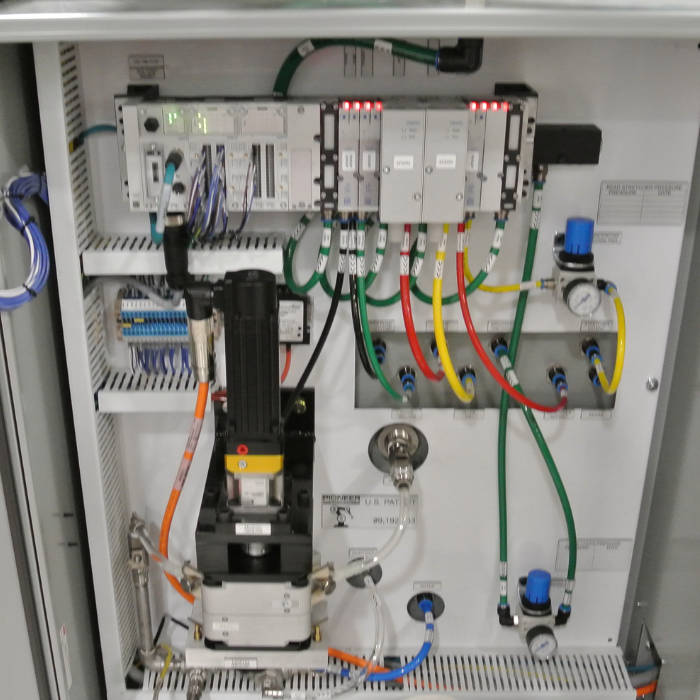

- PFDS(Precision Fluid Delivery System)which includes servo controlled pump to meter the amount of paint supplied to the spray gun

- Automatic water purge

- Agitator for PFDS holding tank

- A/C unit in place of filter/fan for main electrical cabinet

- Upgrade to Allen Bradley ControlLogix PLC (standard CompactLogix)

- Servo controlled lowering table (standard lowering table is pneumatic)

- Individual proportional valves for each chuck to control chucking pressure based on tire size

- Tool free quick change chuck cleaning brushes

- Chuck cylinder upgrade to heavy duty repairable Parker cylinders

- Blocking port for chuck cylinders

- Bead Stretcher integrated into the lift cross

- Graco drum agitator w/ pneumatic lift assist

- Outside tire spray (increases cycle time)

- HMI relocated next to the paint area. (standard location is in the side of the main electrical panel)

- Recipe based spraying, requires barcode

- Torit wet mist collector

- For commercial truck tires,upgrade to DTS2000i model

DTS1000i Feature Highlights

| DTS1000i Specifications | ||

| Bead Diameter | 12″ – 24″ | 305– 610mm |

| Max Bead to Bead Width | 24″ | 610mm |

| Min Collapsed Bead Height | 8” | 203mm |

| Max Tire OD Diameter | 39.5″ | 1003mm |

| Max Tire Weight | 120lbs | 54kg |

| Inside Tire Spray | 360 degrees | |

| Outside Tire Spray | Optional | |

| Cycle Time | 12 tpm, 720tph, 17280tpd (avg tire size) | |

| PLC | Allen Bradley Compactlogix | |

| HMI | Allen Bradley Panelview Plus 7 10” display | |

| Tire Measurement | Light arrays (OD/ID, & Height) | |

| Spray Gun | Devilbiss quick change manifold | |

| Spray Gun Pattern | Variable | |

| Atomizing Air | Variable | |

| Fluid Delivery | 5 gallon Pressure Pot | |

| Tire lube | Water based—no solvent | |

| Purge | Manual flush | |

| Chuck Cleaning | Fixed brush | |

| Electrical Service Req’d | 480v/3ph/60amp or 380V | |

| Air Service Req’d | 1″ drop @ 80PSI (5.5bar) min 20CFM (570lpm) max | |

| Water Service Req’d | 3/8″ drop @ 30psi max (for purge) | |

| Machine footprint | 16’-8” x 20′-8” | |

| Overall Height (frame) | 9′-7” (frame) 12’-3” (top of exhaust fan) | |

| Conveyor Passline | 44” | |

| Exhaust Fan and Filters | 5hp 28”Dia, Slide in re-usable filters | |

| Side-draft booth | HR Steel | |

Pioneer’s DTS1000i Green Tire Sprayer is ideal for Radial or Bias-Ply Passenger and Light Truck Tires

Our patented Precision Fluid Delivery System produces significant material savings and improved quality.

A low cost pressure pot spray system is available.