Automated Assembly Machine Case Study

Customer, Challenge & Risks

Solution

Through word of mouth and past colleagues’ introductions, we met with the customer to discuss their issues firsthand and their vision for automation. Based on our extensive knowledge and expertise in custom design-build projects and a team with capabilities to match, we helped guide their vision to a reality. The automation portion supplemented a company-wide initiative to expand their facility and procure additional equipment, nearly doubling their existing square footage. Our customer forecasted less than a two-year ROI on the automated assembly equipment, which their contract far exceeded and allowed them to pursue additional business that their previous resources did not.

There were some bumps along the way dealing with never ending supply chain delays in an unstable market. It was paramount that we were able to meet the customer’s timeline and expectations while ensuring our own employees health and safety. Also being an SME in the same geographical area, we understood our customer’s pain points by struggling to find willing and qualified personnel and follow strict health and safety guidelines; All the while needing to conduct business as usual.

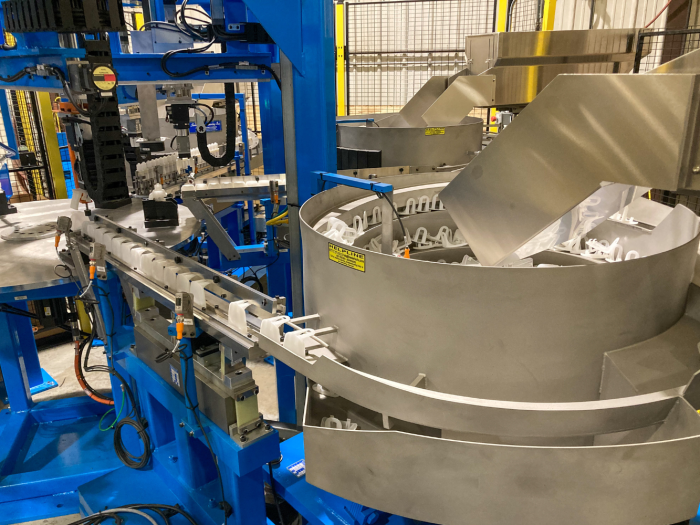

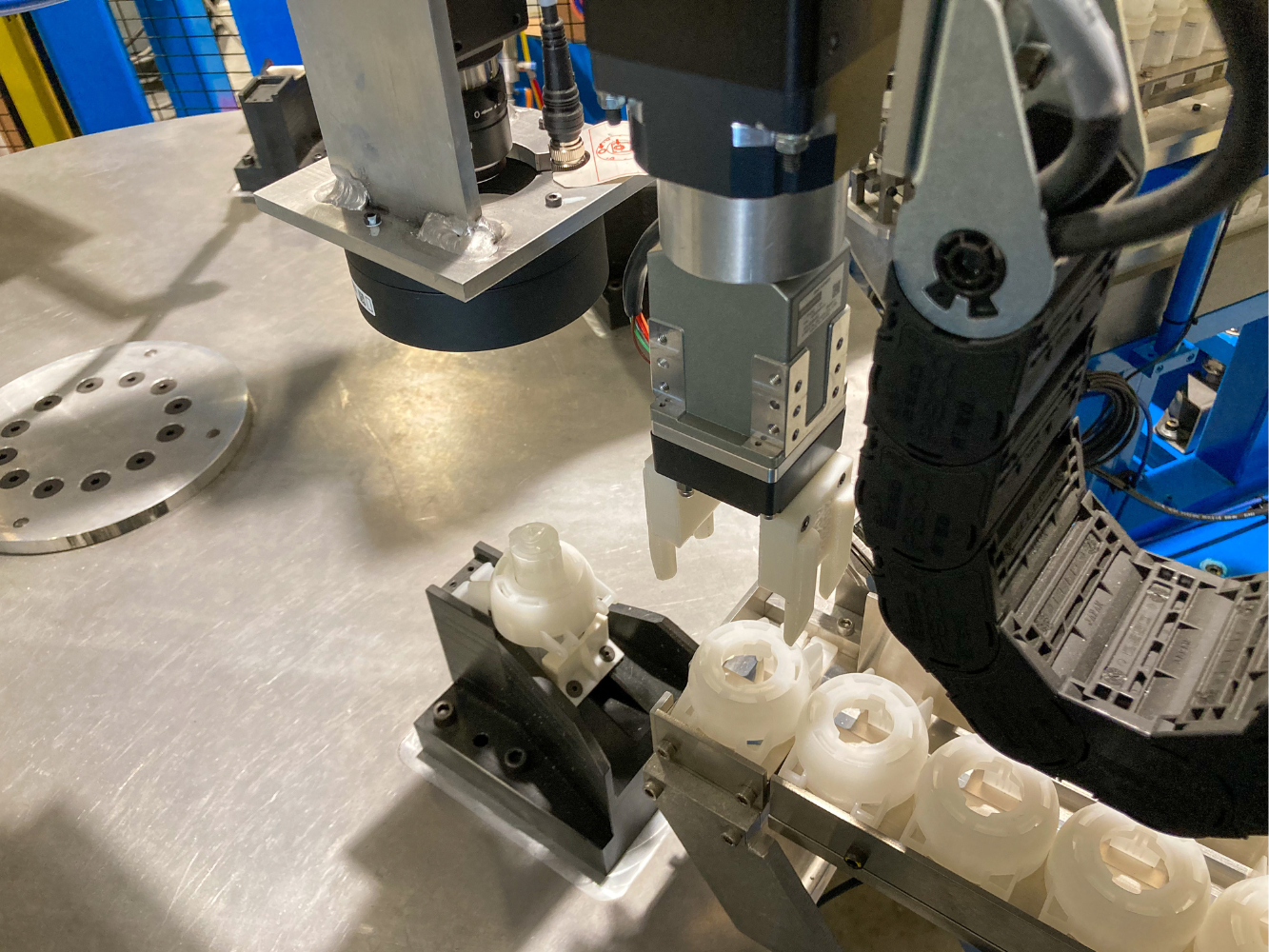

The system was originally intended to be robotic but due to cycle time and budget it was decided to go a route that was more suitable for the application; integrating two axis linear actuators, paired with a fixtured indexing turntable, and designated bowl feeders to feed components into the system. Installation, commissioning and start up were all included in the project scope, which also included a oneyear warranty on material and labor, all which was discussed, agreed upon, and documented during the sales process.

Outcomes of Success

By implementing automation into their existing process, our customer was able to increase throughput 2x with less overhead, reduce potential safety risks from repetitive wrist and hand strain leading to injury, improved quality by repeatability, and introducing inspection throughout the process, which all leads to increased profits. At completion we exceeded our customer’s expectations by solving their immediate and future labor issues, staying within their budget, and delivering on time, which satisfies our internal motto: “Ship on time, on budget, and complete.”

Health & Medical

Material Handling

Mechanical design and engineering

PLC & HMI programming

Installation

Startup support

Fabrication and Machining

Pioneer’s HP/CS Tire Marking is ideal for Radial Passenger and Light Truck Tires

Our integration of FANUC Robots can help you automate your process, improve quality, reduce labor,

and save money.